Description

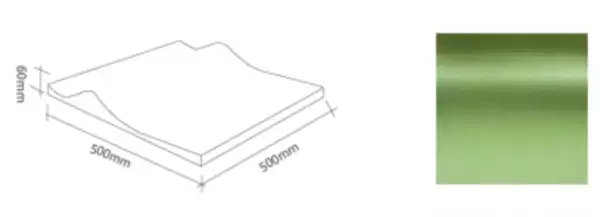

3D Wallboard With Vertical Ripple

Characteristics of 3D Wallboard

Made of 100% polyester

Thickness: 60mm

Length: 500mm

Width: 500mm

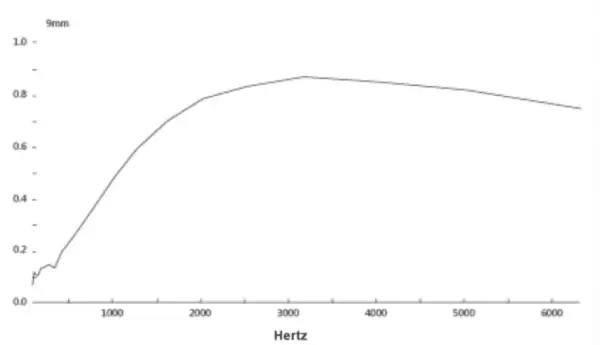

Absorption Class:

NRC: 0.90

Flame Retardant Rating: ASTM E84 Class A

EN13501 Class B

GB8624

Applications: Commercial Office I Hospitality I Theatre I Institutions I Retail I HealthcareEducation I Audio Visual I Branding I PET Furniture I Trade Shows I Signage

How to Install 3D Wallboard?

Recommended supplies

Wallboard – Qianqiang primer-sealer – contact adhesive

Tools: Viscous paint roller, Pressure scraper, Paint bucket, Roller or HVLP paint sprayer, Daohecheng electric construction, Putty knife, level, Ruler painter tape, Sand block

Step 1: surface preparation

habit wall Flats-3D wallboards are suitable for relatively flat and light surfaces. Ensure the surface is clean before installation. Note: the panel should adapt to at least 48 before installation

Step 2: Plan

Use a level to mark lines on the wall to ensure straightness and accuracy. It is allowed to cut panels in more inconspicuous areas, such as corner walls and the bottom of walls. If you work from the center outward, you may want to cut the panel with eaves at the edge. Plan your design to ensure the desired results. Please remember to measure twice and cut once

Cutting panel tips: you can use a standard art knife or electric tools to cut the wall panel. We recommend drilling along the cutting line or with paintwork glue when using power tools to reduce pulp talent. We recommend blades, drills, etc… designed to complete the work. When using electric tools, please follow the manufacturer’s use and safety recommendations

Step 3: 3D wall panel installation

Confirm whether the installation is a floating design with wall-to-wall and uniform boundary, a panel, etc. Plan before you start again. If you are not sure, please put the panel on the floor or draw a sketch

Install with contact cement, following the manufacturer’s recommendations for painting on walls and panels and the working time before adhering to the wall

After the board is in place, apply pressure around the perimeter of the panel and other contacts on the wall to lock it in place. After installing all panels, apply pressure to the entire plane to achieve full adhesion

Step 4: complete the 3D wallboard

Langham – after the panel adheres to the wall, the primer and sealing coat shall be applied before any finishing work. Primer Dongguan protthe ects the panel during finishing

Seamless installed filler joint (optional)

For the previous almost seamless installation, we recommend that the panels be spaced 1/16 inch apart. Fill the gap joint compound. The first layer is used to fill the gap. Keep clean. If you need to grind quickly to make the seam flat, do it between the coatings. Do not polish the second coat too much. It should be in order to form a smooth transition between panels. The final grinding will require a perfect mixing table. If you need to go back, it’s time to treat some areas with additional compounds and sanding

The arrangement around the socket and switch uses the expansion box of the socket and switch to lead them out of the wall panel. Cut the panel to fit the opening of the box and complete the caulking around the edge.

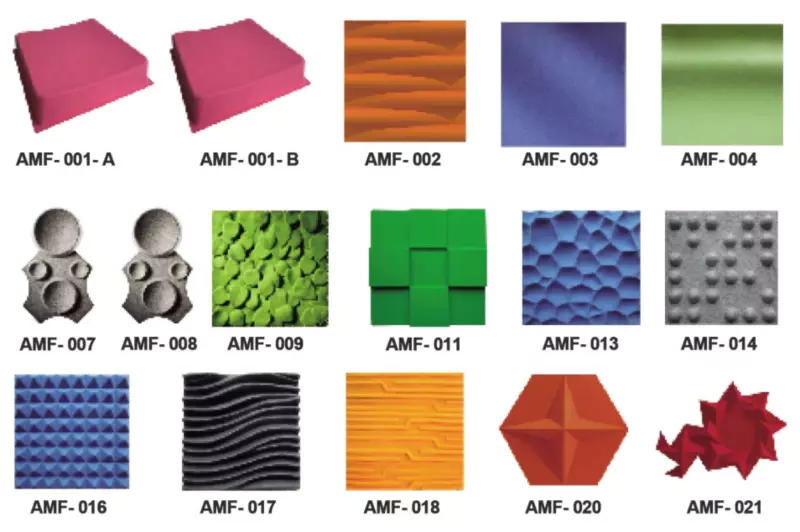

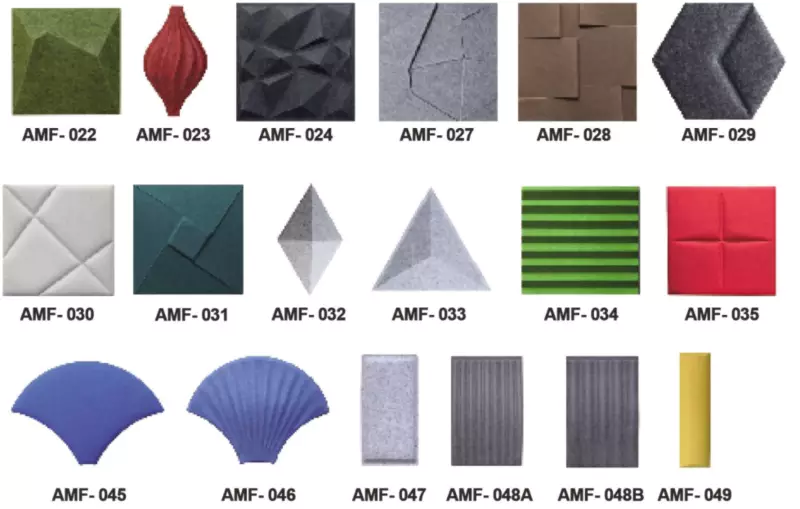

3D Wallboard With Various Patterns

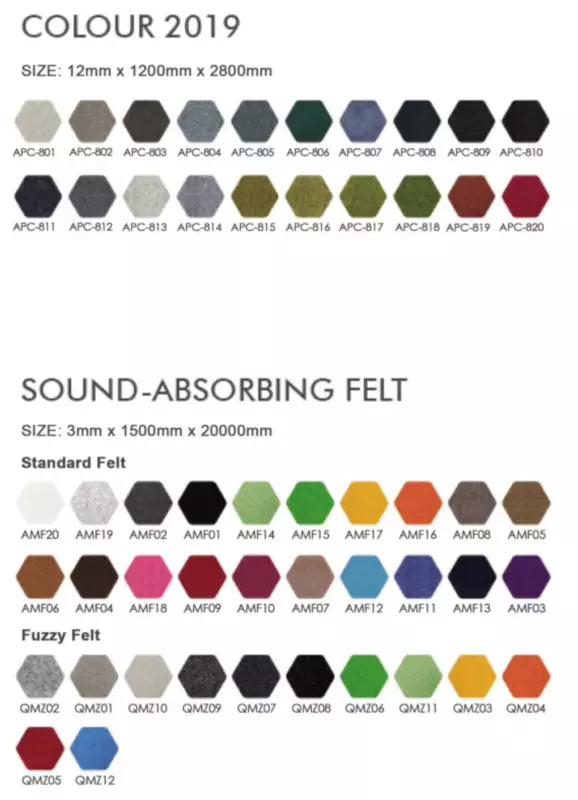

These Colors You Can Choose

3D Wallboard Factory

The company is a manufacturer of environmental protection building materials for production, sales, and development. It has domestic advanced automatic molding equipment and production technology and has a professional mold research and development team and efficient production capacity. The products have been exported to many countries in the world and are deeply loved by consumers in various countries. The sales volume has been on the rise. Support foreign trade companies to provide one-piece services, and ensure the quality and service of professionals.

The products are mainly used in: the wall background of the company’s meeting room, the background wall of hotels, the background wall of exhibitions, exhibitions, exhibition halls, display cabinets in various industries, the background wall of home decoration TV, the background wall at the head of the bed, the background wall of living room sofa, the background wall of staircases, aisles and other wall decoration.

The main features of this product are environmental protection, fire and moisture prevention, collision prevention, sound insulation, heat insulation, high-end texture, fashionable design, and real three-dimensional effect.